Truss Design Project

Design and construct a truss using only toothpicks and superglue

Mechanics and Design Final Project

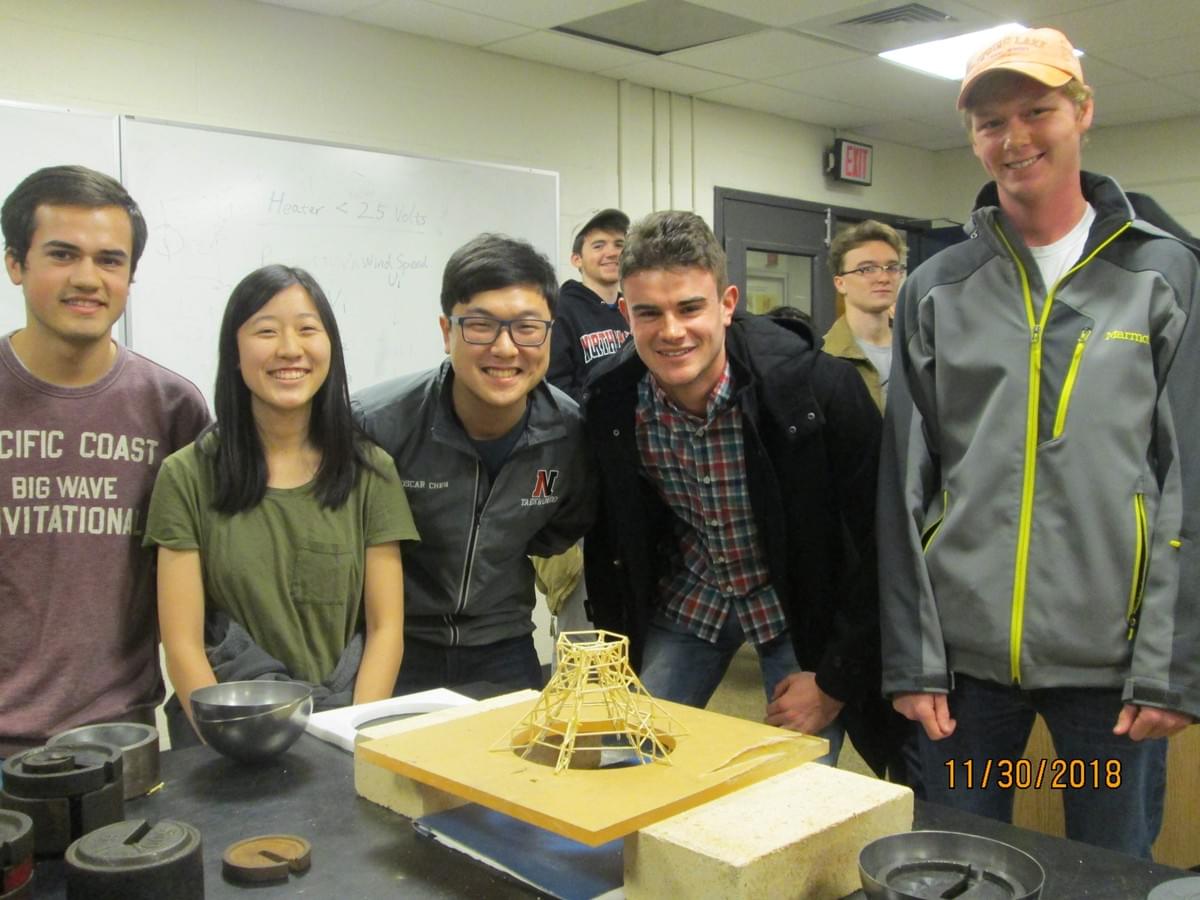

The goal for this project was to design and construct a 3D truss that could hold 20N. Our team set goals to create a low cost truss with high strength that was aesthetically pleasing. Our final model weighed in at 20.6 grams and supported a maximum mass of 9.1 kilograms.

Team photo right before testing

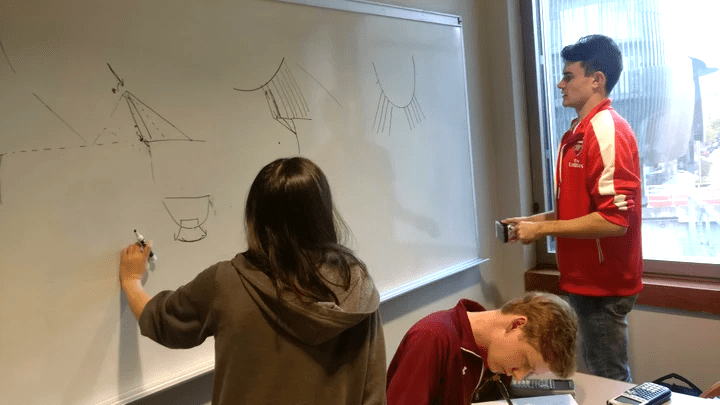

Brainstorming and Designing

Our first few meetings together as a team were to breakdown the parameters we had to work around and ideate designs with certain mechanical and theoretical understandings in mind.

Assembling Individual Trusses

With some designs in mind, we thought as a team what the most efficient method would be to accurately and cleanly superglue small pieces of toothpicks together. With a laser cutter at our disposal, we laser etched and cut onto pieces of plywood templates of our designs to more easily assemble the trusses.

Testing Day

With everyone's trusses assembled, we all surrounded each other as we nervously placed more and more weights onto our models.

Conclusion and Results

Our truss design lacked strong members supporting itself from a rotational moment that we did not particularly account for. We had horizontal members connecting each 2D truss we assembled, but these horizontal members should have in fact been glued diagonally to support against this rotational moment.